Any company seeking to remain competitive over time undergoes continuous transformation to enhance operational efficiency, reduce costs, minimize unplanned downtime, and extend the lifespan of assets.

To achieve this, they can turn to a Computerized Maintenance Management System (CMMS), which, besides being a technological tool, enables you to adopt a strategic approach to managing your assets' maintenance. This approach helps your organization keep its operations in optimal condition, increase productivity, and maximize return on asset investment. In fact, Odoo features a dedicated application specifically for Maintenance Management; we'll delve into it further below.

What is a CMMS?

A Computerized Maintenance Management System (CMMS) is a tool designed to enhance the efficiency of maintenance operations by providing a centralized platform for planning, executing, and tracking all activities related to asset and equipment maintenance. It uses standard statistics calculations to aid in planning preventive maintenance, including Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR), as well as predicting the next failure date. It also automates metrology and preventive maintenance scheduling. Odoo's Maintenance application serves as an excellent example of a CMMS.

In summary, with this software and approach, you can schedule both preventive and corrective maintenance tasks, manage your assets, generate reports, track maintenance histories, and optimize your inventory of parts and spare components.

Why Do You Need a CMMS?

A CMMS becomes essential when aiming to streamline time and costs in maintaining a company's assets. Facility management within companies is often handled by a small number of personnel. According to a 2023 survey, the percentage of facility management employees responsible for cleaning/maintenance of spaces ranging from 92,903 to 185,806 square meters reached nearly 20 percent of total respondents—an extensive area for one person to cover.

Utilizing a tool like Odoo's Maintenance application, alongside a strategic approach, empowers your team to proactively address maintenance needs, offering these eight possibilities:

Operational Efficiency: Schedule and manage maintenance tasks more efficiently, reducing unplanned downtime and enhancing your organization's overall productivity.

Asset Management: Track and manage your assets more effectively, extending their lifespan and ensuring optimal use.

Preventive Maintenance: Facilitate a proactive maintenance approach, helping prevent failures.

Regulatory Compliance: For regulated industries, you can maintain precise records of inspections, certifications, and required maintenance to meet regulations.

Informed Decision-Making: Access valuable information for making informed decisions about maintenance strategies and resource allocation.

Cost Reduction: Efficiently planning and scheduling maintenance aids in minimizing expenses related to unscheduled repairs, and optimizes spare parts management.

Enhanced Safety: Proper maintenance contributes to employee safety and asset integrity, reducing operational risks.

Historical Records: An application like Odoo's Maintenance stores a complete history of maintenance and repairs, enabling trend analysis and identification of recurring issues.

How to Add a New Equipment to Your Odoo Maintenance Application?

Within your Odoo instance, the term "equipment" refers to any item within your assets that is used in daily operations, such as product manufacturing. This ranges from machinery on your production line, and tools, to office computers. These pieces of equipment can be owned by the company with the Odoo instance or by a third party, such as a supplier.

Within the Maintenance application, you can track individual equipment parts along with their maintenance requirements.

Add new equipment to your Odoo Maintenance application following these 5 steps.

1. Go to your Maintenance application.

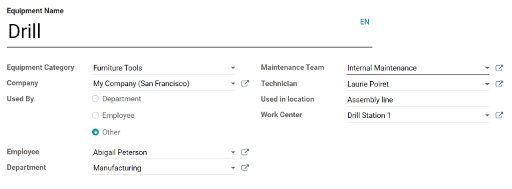

2. Select Equipment > Machines and Tools > New

3. Configure with:

Equipment Name

Equipment Category

Company

Used by

Maintenance Team

Technician

Used in Location

Workplace

4. Include additional product information

Supplier

Supplier Reference

Model

Serial Number

Effective Date

Cost

Warranty Expiry Date

5. Add maintenance details

In the Maintenance tab, include information useful for personnel responsible for asset management, such as:

Preventive Maintenance Frequency: Specify how often maintenance should occur to prevent equipment failures.

Maintenance Duration: The time required to repair the equipment when it fails.

Expected Mean Time Between Failures: The average time the equipment is expected to function before failing.

The maintenance tab also includes sections for Mean Time Between Failures, Estimated Next Failure, Last Failure, and Mean Time To Repair. These values are automatically calculated based on maintenance requests, if any.